Services

What We Do

We specialize in the R&D and production of liquid crystal display (LCD) modules. Backed by professional technology and strict quality control, we deliver high-stability and high-definition premium products. Going forward, we will take technological innovation as the core, and work hand in hand with global partners to create new value in the display industry.

FAQ (Frequently Asked Questions)

Who is “XY factory” ?

XY phone LCD factory, an experienced team which is dedicated to premium and top class phone screens, including AMOLED, OLED, LCD (In-cell, On-cell), TFT display screen replacements for iPhone, Samsung, Google, Infinix, OnePlus, Oppo, Tecno, Vivo, etc..

XY phone LCD factory is the top and leading unit in wholesaling mobile device replacement screen industry. We offer unmatched quality, fast fulfillment, shipping from multiple distribution centers, industry-leading support and knowledge base.

What Phone Parts does “XY phone LCD factory” supply for me?

“XY phone LCD factory” supplies AMOLED, OLED, LCD (In-cell, On-cell), TFT display screen replacements for Phones

How do I get your catalogue or price list?

Please leave your info and we will contact you as soon as possible, or you could directly friend us with social IM(instant message) APPs!

What are your regular payment methods for orders?

Generally speaking, we accept the payment methods via TT (International Bank Transfer), Credit card(VISA, Mastercard), Alipay, WeChat Pay, etc..

Do you OEM and ODM?

Both OEM and ODM are both optional.

Automatic LCD Terminal Cleaning Machine

The Automatic LCD Terminal Cleaning Machine is a professional automated cleaning device specially designed for the production process of liquid crystal display (LCD) modules. It is mainly used for high-precision cleaning of dust, residual solder flux, fingerprints and other contaminants on the terminal parts of the modules.

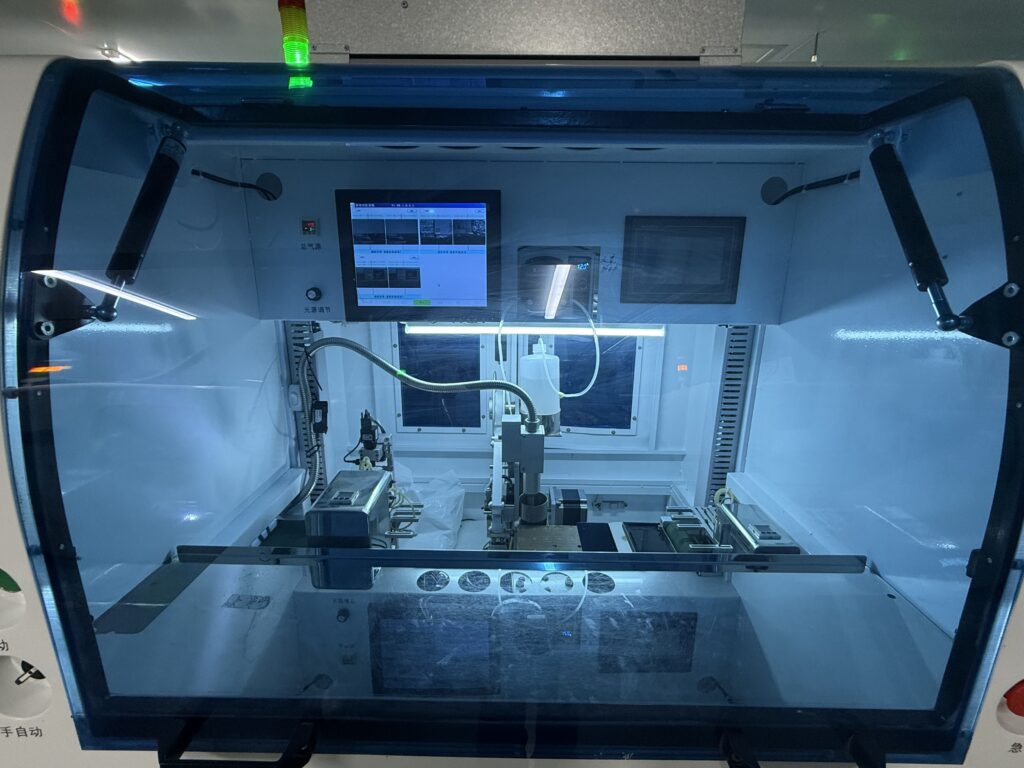

Chip On Glass Bonding Machine

IAutomatic COG Bonding Machine is a core automated device for the production of Liquid Crystal Module (LCM) and Touch Panel (TP) modules, mainly used for accurately bonding driver IC chips onto the circuits of glass substrates..

Its core advantages lie in micron-level alignment accuracy (up to ±1μm), stable thermocompression parameter control, and flexible production capacity compatible with glass substrates and IC chips of different sizes. It can effectively improve product yield, reduce labor costs, and is widely applied in the large-scale production of display modules for mobile phones, tablets, vehicle-mounted displays, industrial control screens, etc.

Automatic Backlight Assembly Machine

Automatic Backlight Assembly Machine is a key automated device in the manufacturing process of Liquid Crystal Modules (LCM), mainly used to complete the automatic assembly procedure of backlight modules. As the core light source component of liquid crystal displays, the assembly accuracy of backlight modules directly affects the brightness uniformity and display effect of the screen.

The equipped visual inspection system can recognize material defects and assembly deviations in real-time, effectively improving product yield and reducing labor costs. It is the core equipment in large-scale backlight module production lines.

Request a Quote Today

Reach Us

Location :

Room 301, No. 13-2

Gufeng First Road, Xintian Community, Guanhu Street, Longhua District,Shenzhen,Guangdong province, China

Email :

m15797786120@gmail.com

whastapp:

+86 18123603787

+86 15797786120